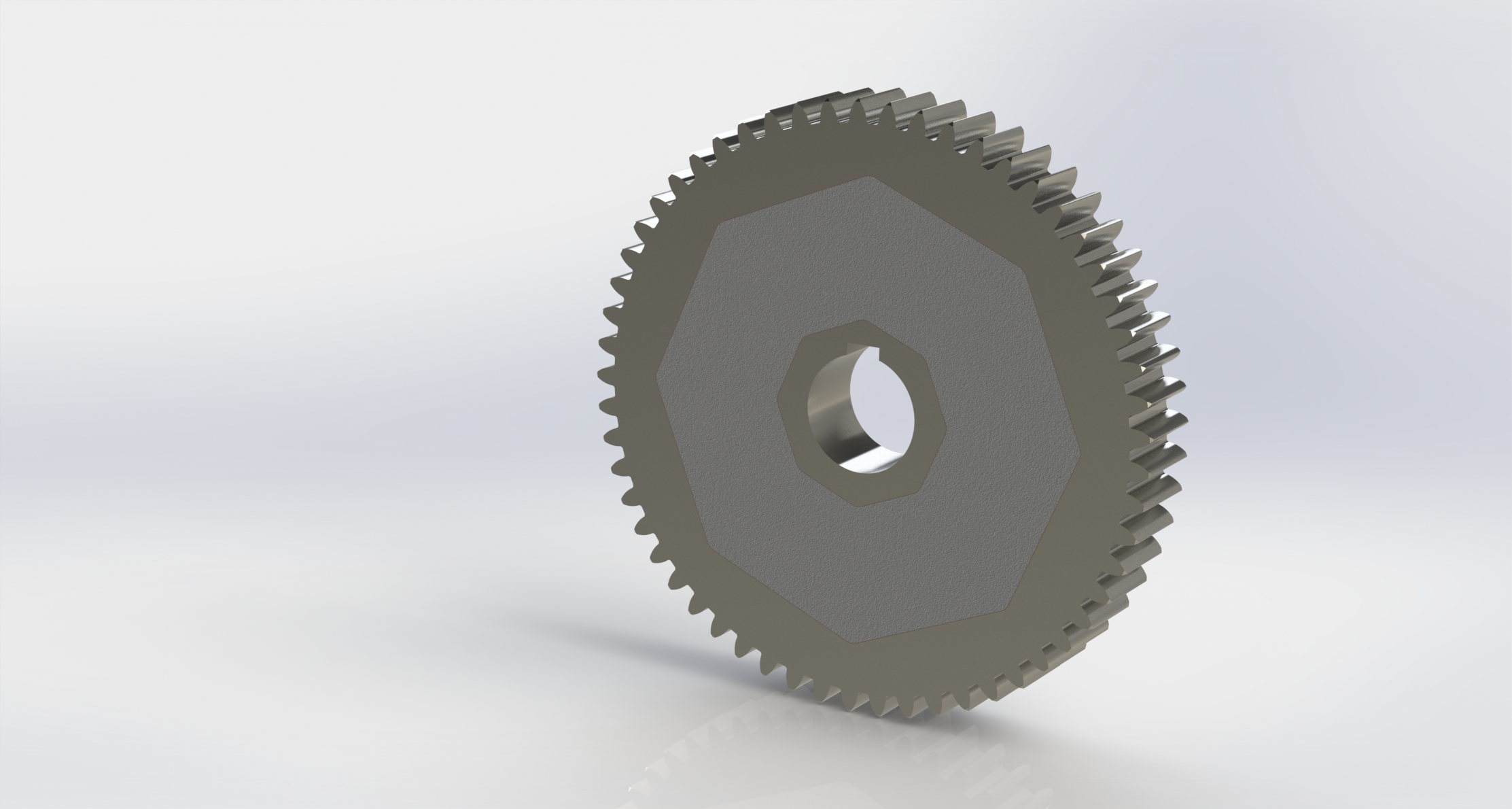

Hybrid Composite Gear

The aim of this study is to produce composite gears that approach or better the characteristic curve of the steel gear.

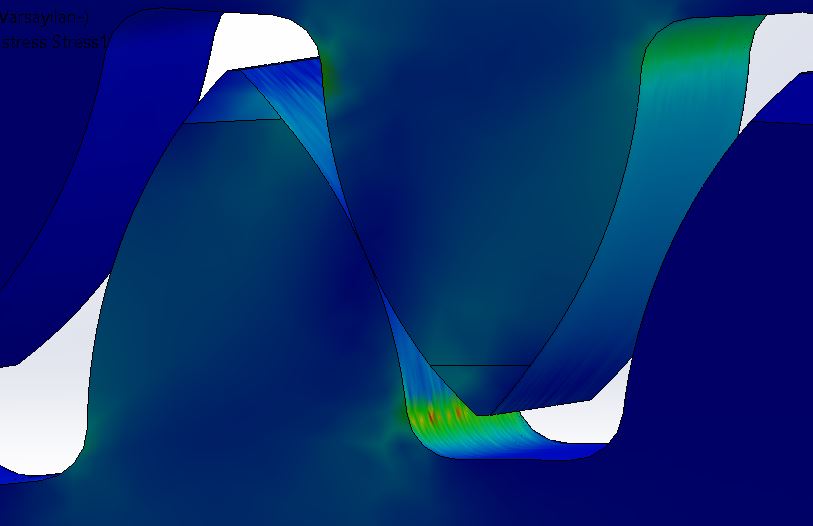

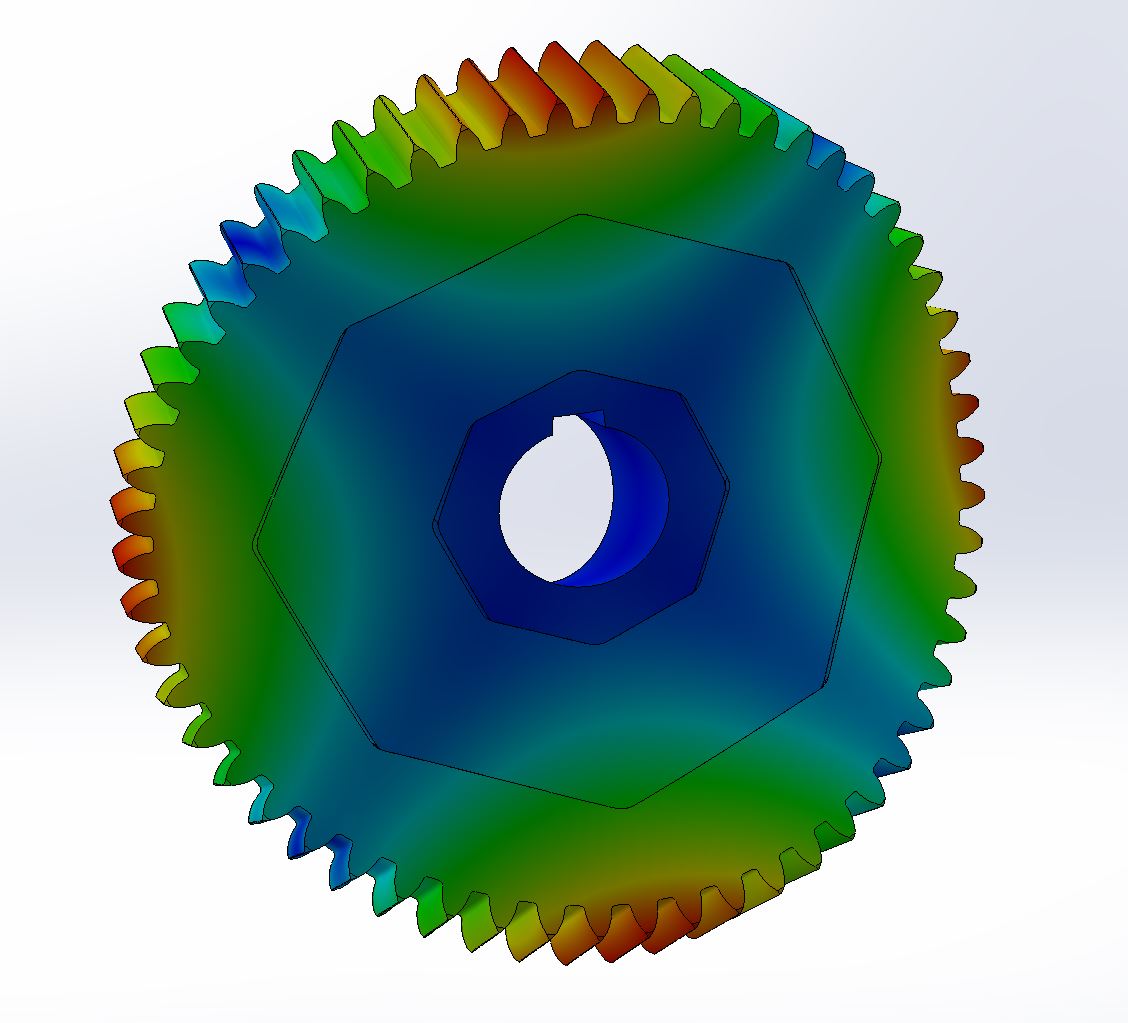

In this study, the aim is to produce composite gears that approach the characteristic curve of the steel gear or have better characteristics. In this way, the design is lightened without moving away from the force/deformation ratio of the gear. For this, first of all, material selection should be made. Analysis was made in the computer environment and material selection was made using these analyzes. As a result of the static, frequency, and buckling analysis tests of hybrid gears, the characteristics of the materials were obtained, compared, and evaluated accordingly.

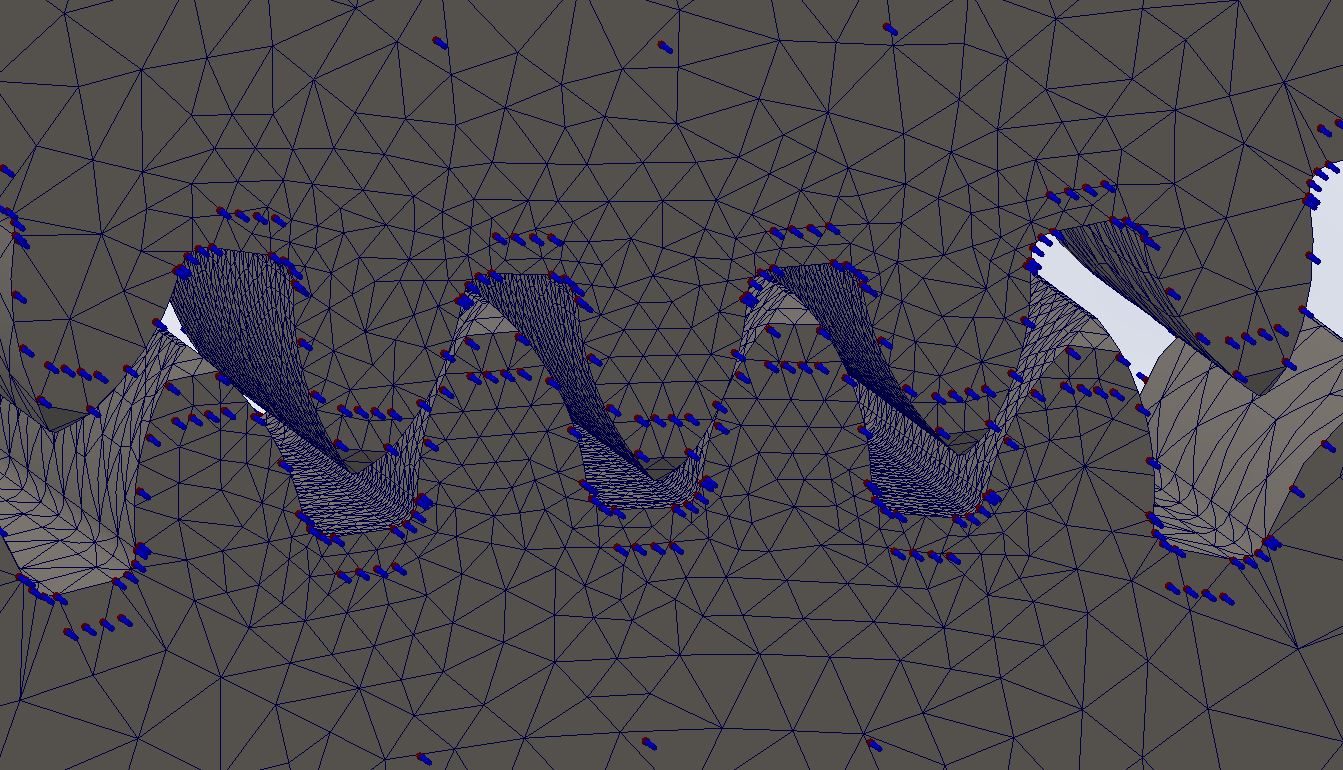

Then, the geometric analysis stage started. To decide the shape of the geometry to be extracted from the steel part, analysis was performed for multiple different geometric shapes under the same conditions. Static and frequency analyzes were made to decide on the dimensions of the steel part to be removed as an optimization study for the selected geometries. Finally, mold models were designed for the production of the decided geometry.

You can use this link for see all project files.