Hybrid Composite Gear Revision

The aim of this study is to revise the hybrid composite gear design made in June 2022.

In our age, many new materials have been sought in order to meet the needs, and subsequently the science of materials has developed at an advanced level. One of the important developments in gear construction is to increase the damping ability as well as weight reduction. Gear wheels are the most important mechanical power transmission components and very fine details should be taken into account when designing. Hybrid gear wheels will give us the necessary support in this regard. Especially with the development of technology, we encounter hybrid gear wheel designs in aviation, automotive, defense and many fields. In addition, it is seen that hybrid gear wheels have such a widespread usage area that it contributes to many advantages besides gaining weight and damping.

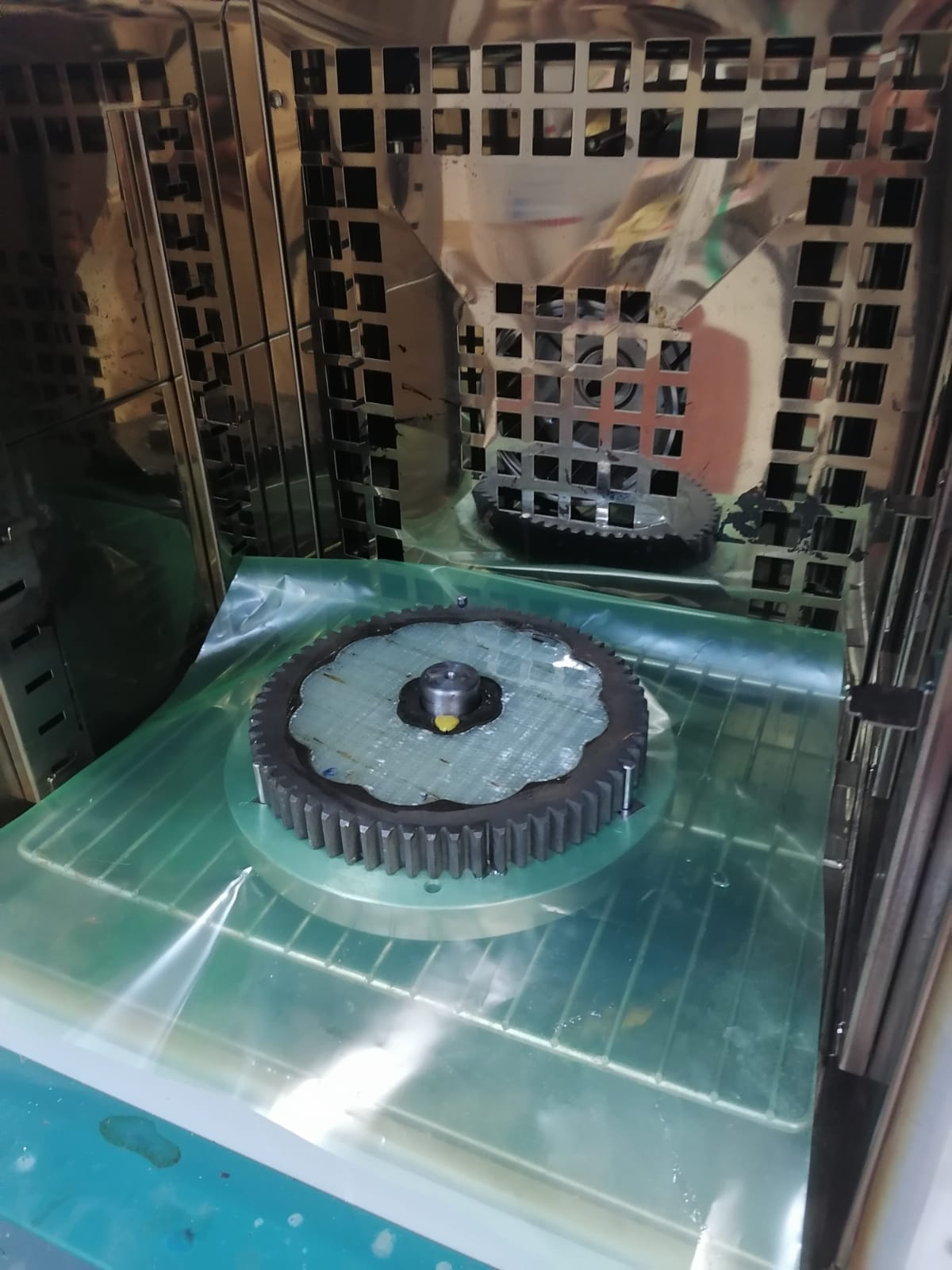

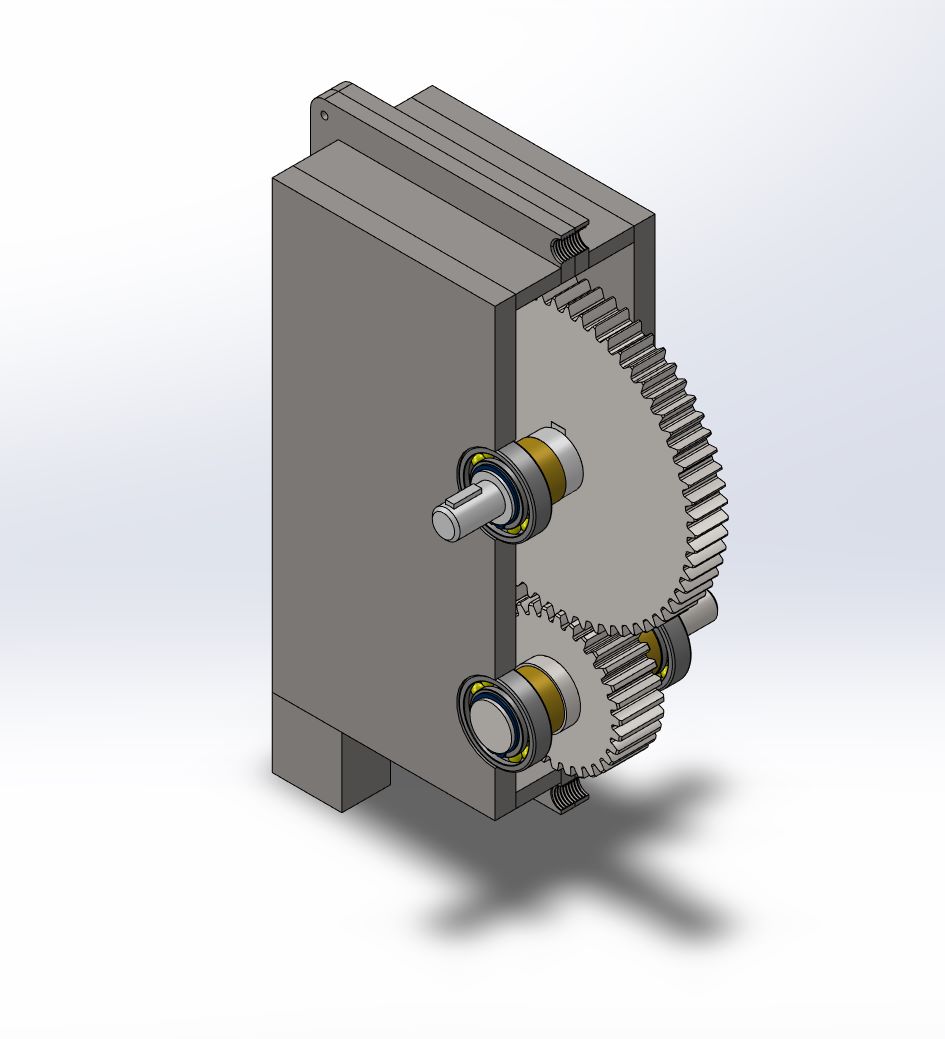

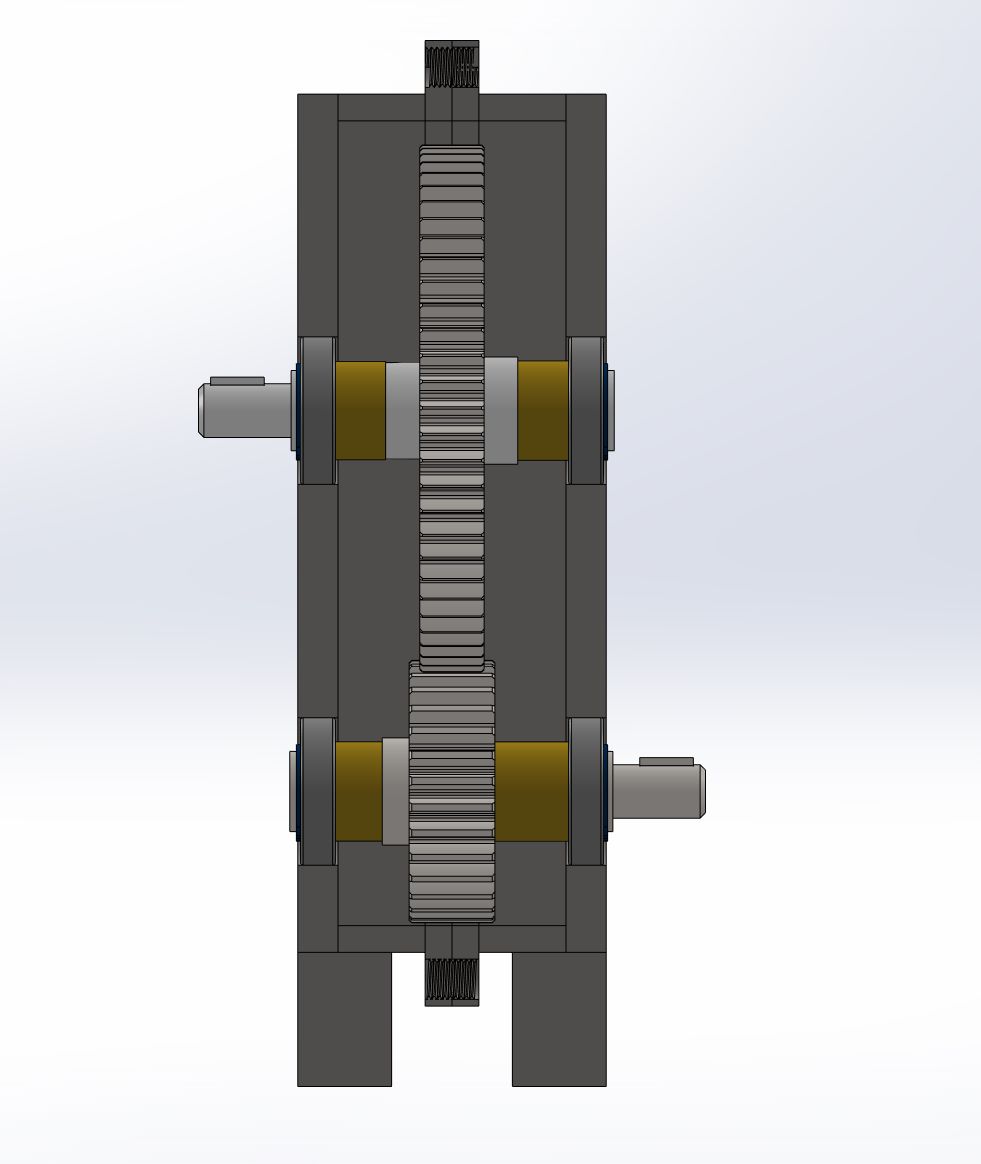

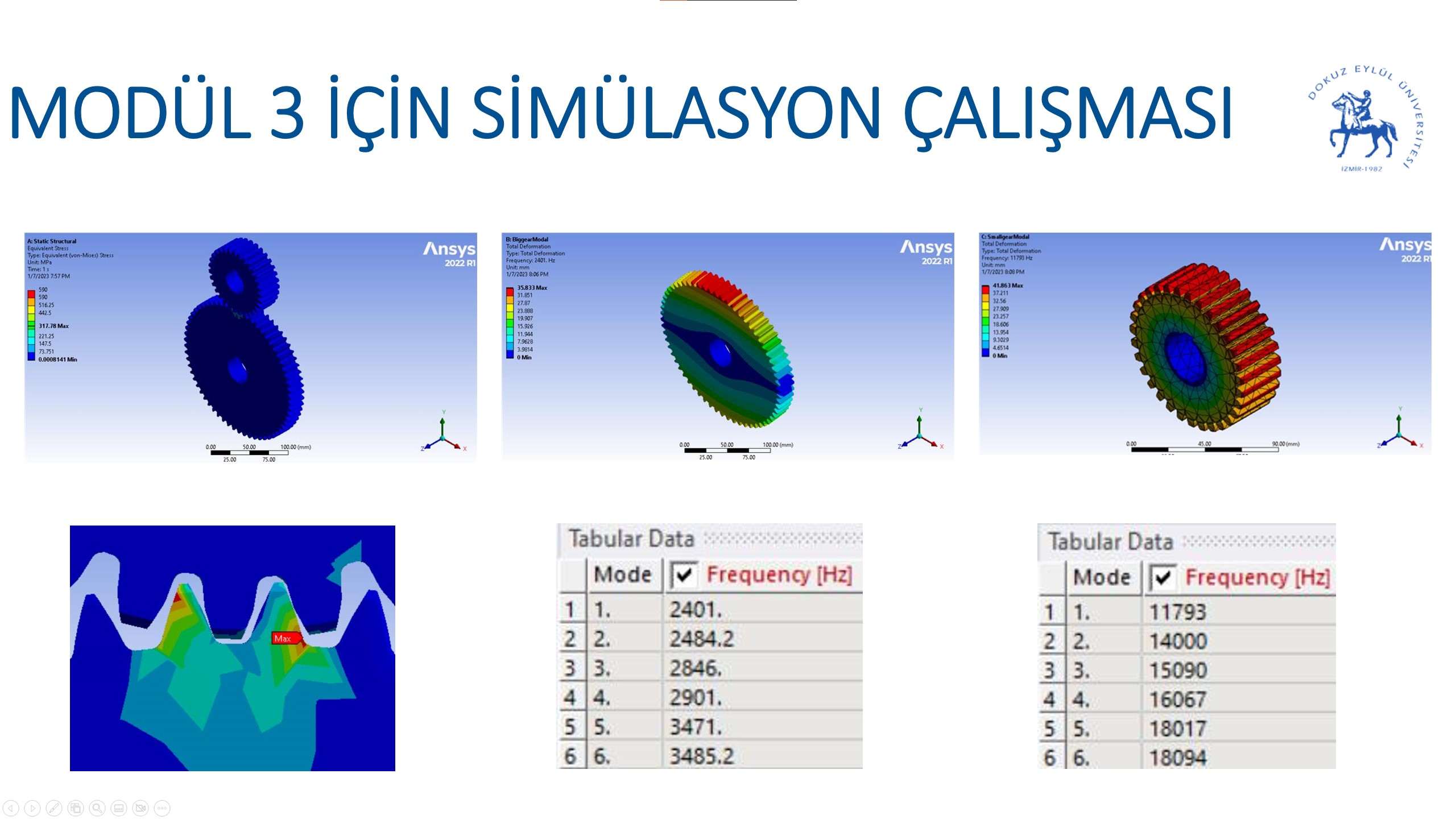

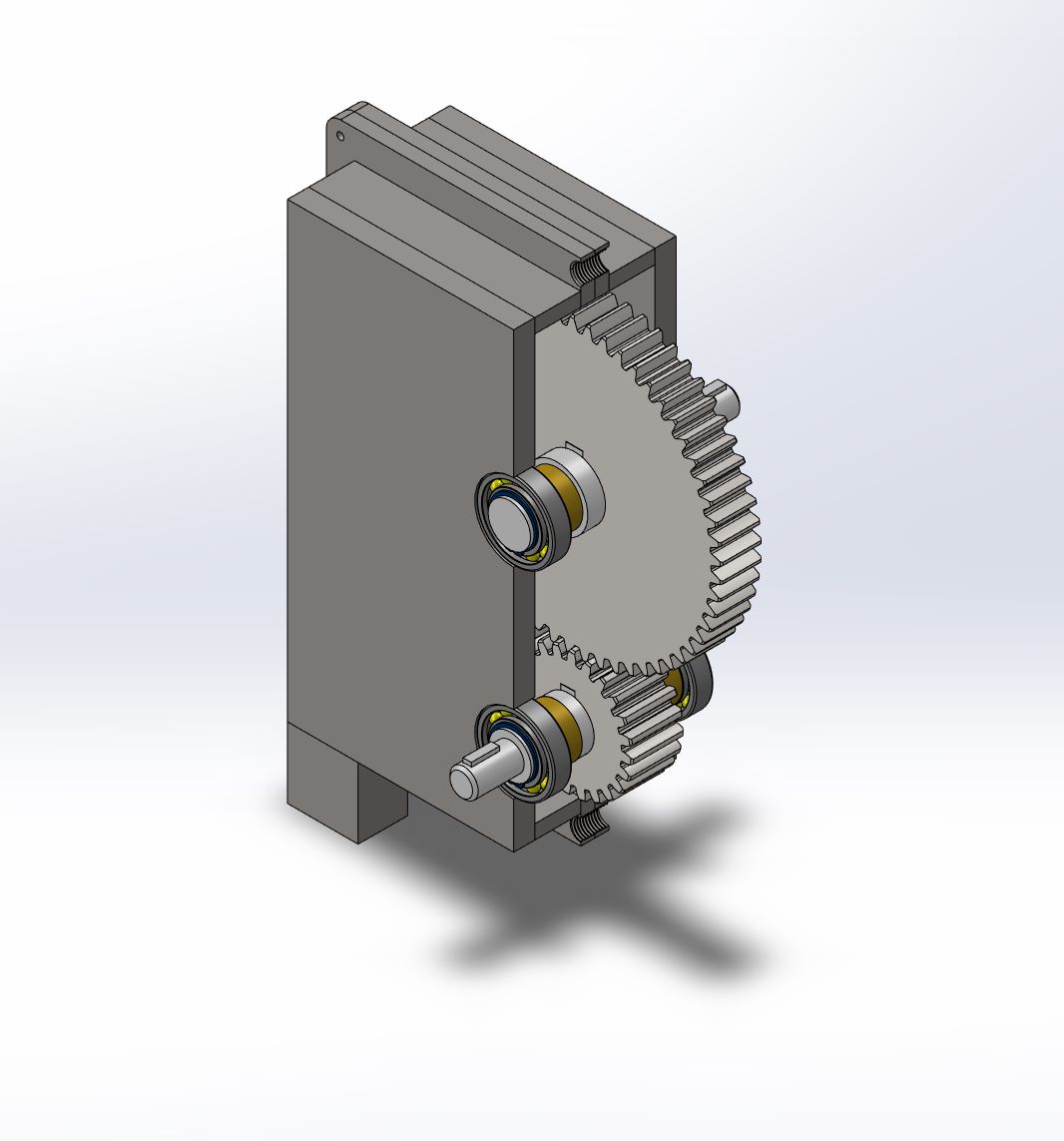

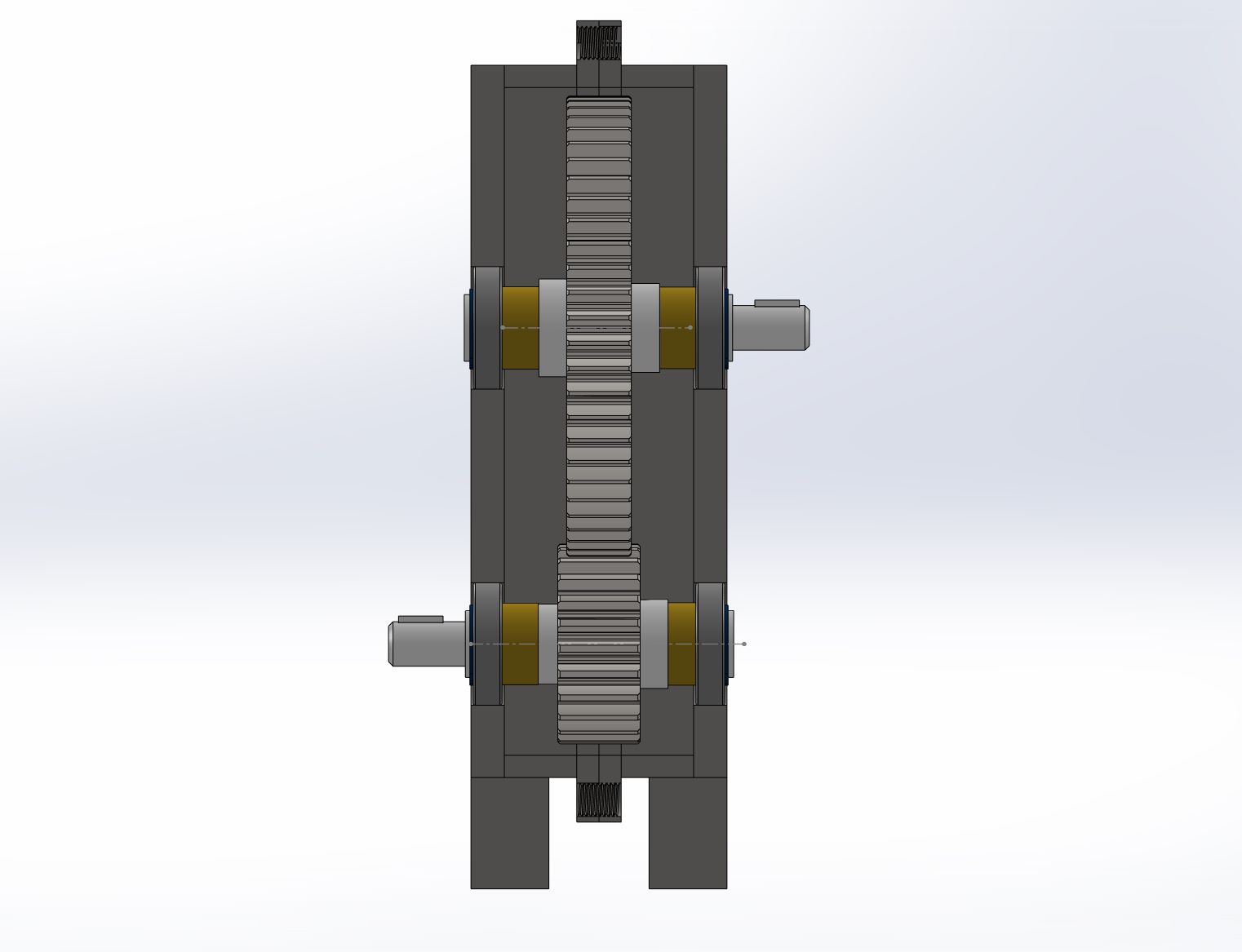

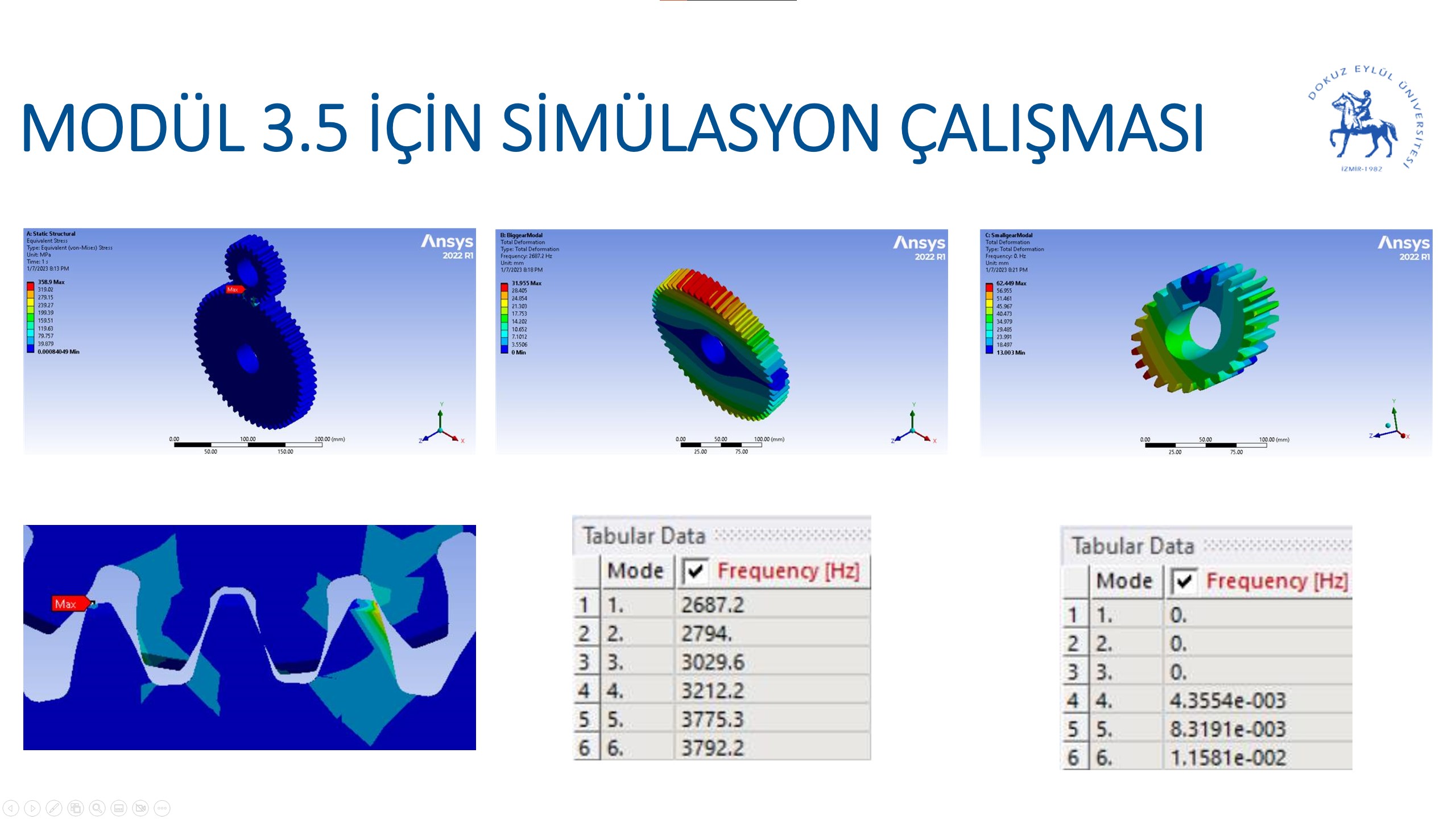

The aim of this project, which has been going on since the past period, is to revise the faulty and missing parts of the project made in the past period and create new designs. After the new designs were made, it was aimed to work on gearbox designs by calculating the shaft. After the pinion and wheel design were made, it was aimed to focus on dynamic analysis by designing hybrid gears and gearboxes using composite plates, glass fiber and carbon fiber materials. In addition, the feasibility of the old study was made and the designs were improved.

You can use this link for see all project files.